Abenab Project

Abenab Vanadium-Lead-Zinc Project

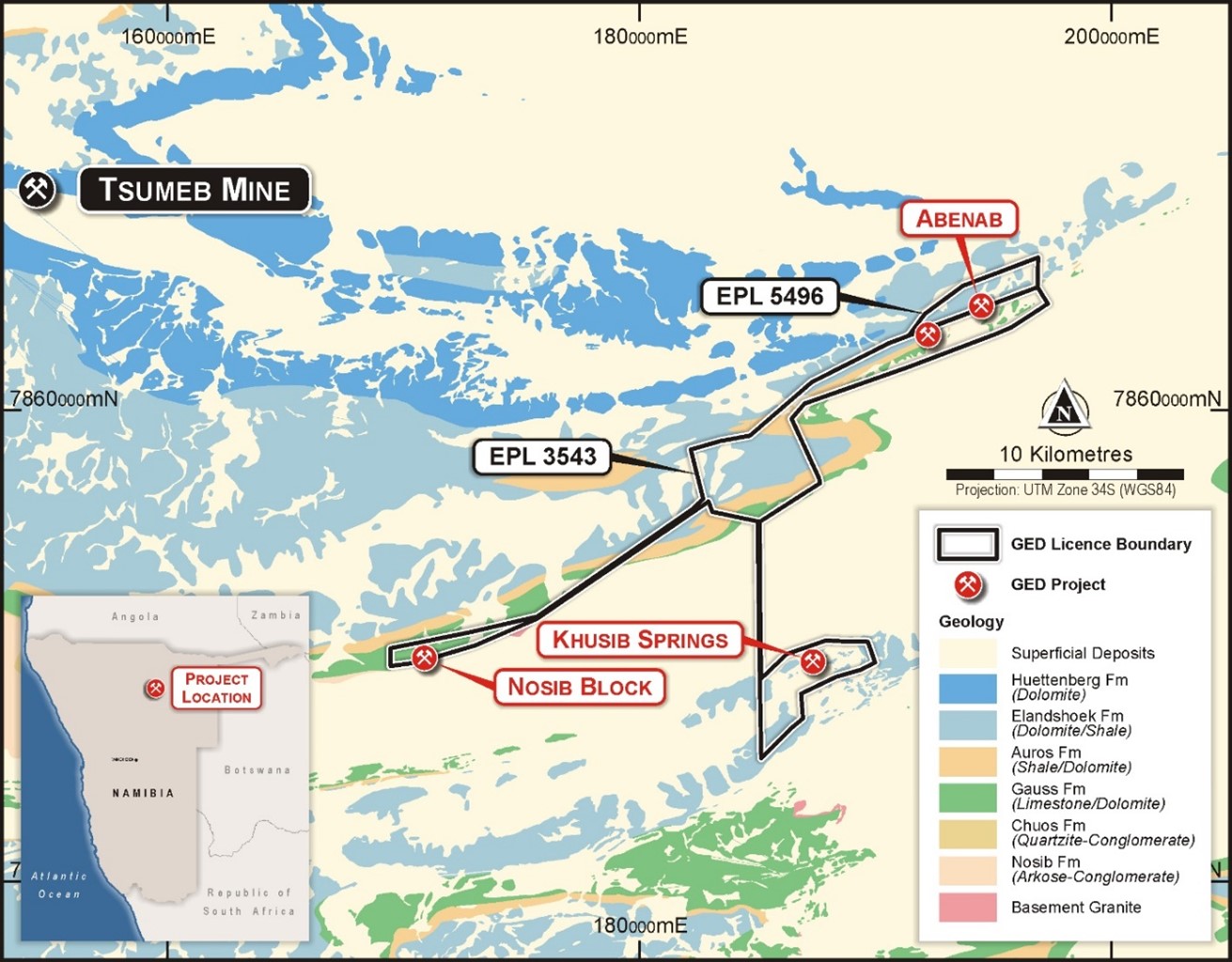

The Abenab Project is located at the northeastern end of the Company’s EPL3543 (Figure 1) and was operated as an open pit and underground mine from 1921 to 1947 by the South West Africa Company. Historical production from Abenab included 176kt of 16% V2O5, 13% Zn and 54% Pb in high-grade concentrate.

Figure 1: Golden Deeps Otavi Copper Belt licences with location of Key Prospects

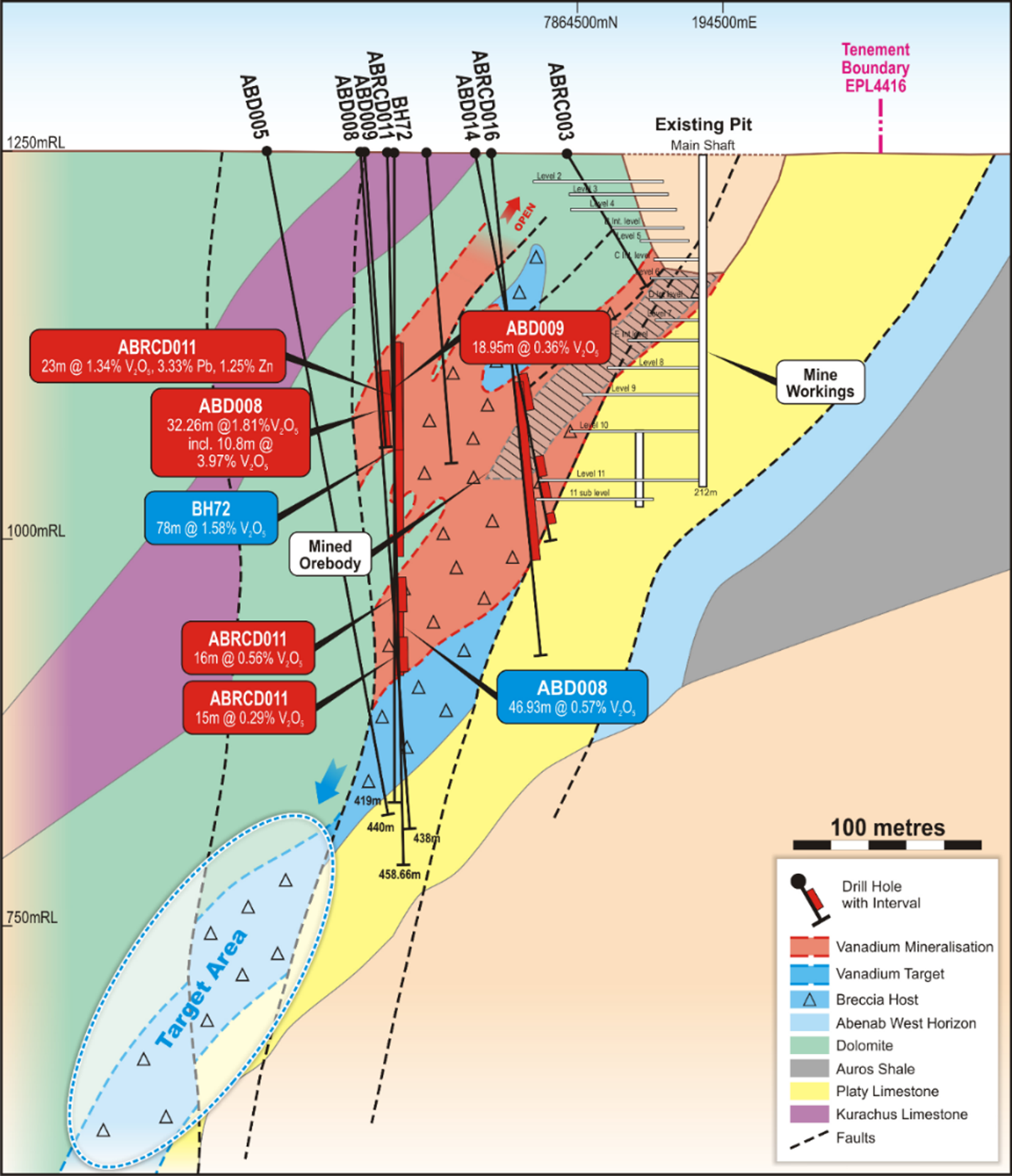

The Abenab mineralisation is hosted by carbonates of the Otavi Group and consists of a pipelike karst breccia of collapsed country rocks cemented by coarse calcite and descloizite-vanadinite concretions. The Abenab Breccia Pipe lies on a steeply dipping sheared contact between massive dolomite and platy limestone (see Figure 2, below).

Figure 2: Cross section Abenab breccia showing mineralisation, previous workings & 2019 drilling

The vanadium mineralisation at Abenab is contained in the minerals descloizite (vanadium-lead-zinc hydroxide) and vanadinite (vanadium-lead chlorovanadate). The vanadium mineralisation takes several forms including breccia clast infill, fine grained fracture fill, open space crystal growth (see Photo 1 below) and clay-filled cavities.

Golden Deeps is accelerating development of the Abenab Vanadium-Lead-Zinc Project, of which it holds an 80% interest and is on track to enter production in 2020.

Metallurgical Testwork:

Metallurgical testwork on the Abenab mineralisation has focused on gravity concentration testwork to concentrate the high-density mineral descloisite. Several phase of testwork have been carried out, culminating in June 2023 with the generation of an exceptionally high-grade vanadium with zinc, lead and copper concentrate bulk-sample grading:

- 15.6% V2O5, 11.2% Zn, 38.2% Pb and 0.8% Cu

This represents an 18 times (x) upgrade of the representative drill-core composite sample, that had an assay head grade of 0.9% V2O5, 2.1% Pb and 0.7% Zn.

The Company has also carried out down-stream hydrometallurgical leach testwork which demonstrated vanadium extraction rates of up to 95% and high extraction of lead, zinc and copper from a lower grade concentrate feed generated from surface stockpiles and tailings.

Mineral Resource Estimate and Development Studies:

The outcomes of both the gravity concentrate testwork and the downstream hydrometallurgical testwork provided processing cost inputs (capital and operating) which were integrated into a new resource model for the Abenab deposit and an upgraded mining study (by Bara Consulting), to produce a scoping study for staged mining, gravity concentration and downstream processing of the high-grade Abenab high-grade V-Zn-Pb resource.

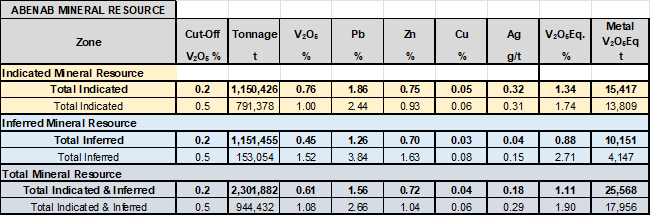

The new Mineral Resource estimate for the Abenab vanadium-lead-zinc deposit (announced 24 June 2024) was prepared by Shango Solutions of South Africa (Shango) and is summarised in Table 1 below:

Table 1: Nosib Prospect, Maiden Mineral Resource estimate

Shango also prepared the previous, January 2019, Mineral Resource estimate of 2.8Mt at 0.66% V2O5, 2.35% Pb and 0.94% Zn (0.2% V2O5 cut-off), which utilised historical drilling by Avonlea Minerals Ltd.

The new Mineral Resource estimate follows further drilling by GED in 2019 which included 18 RC and diamond drillholes for 3,266m which was designed to infill and extend definition of the Inferred Mineral Resource areas identified in the 2019 model. During late 2022 to early 2023 Shango updated the Abenab model in Datamine (all previous models were created in Leapfrog Geo) incorporating the 2019 drilling results for the purposes of refining and optimising the wireframes and block models (see 3-d models, Figure 4, below). In addition, Shango included vertical (normal?) faults, as observed by Shango in the pit wall, which are interpreted to have controlled the secondary vanadium-lead-zinc mineralisation.

Mining studies by Bara Consulting of South Africa and metallurgical gravity concentration and hydrometallurgical leaching testwork provided economic parameters to determine cut-off grade parameters for the reasonable prospects of economic extraction determination.

Underground mining studies on the Abenab Mineral Resources and an open pit mining study on the Nosib Mineral Resource, in progress, are being integrated with the metallurgical/processing studies, to produce a development study (the Study) for the production of high-grade vanadium-copper-lead-zinc-silver concentrate. The Company’s testwork has shown that the concentrate can be downstream processed by acid leaching to produce high-value vanadium products such as vanadium electrolyte for vanadium redox flow batteries (VRFBs) as well as copper, lead, zinc and silver by-products.